Sleeking Technology

Sleeking Technology

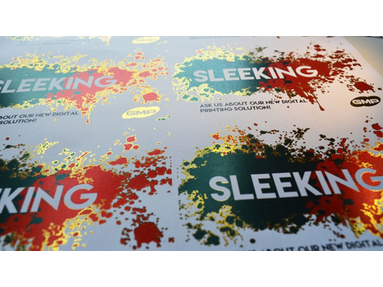

An exciting new laminating technology called ‘sleeking’ has arrived to DBC Group. Sleeking can add an array of optical effects simply with one laminating machine in-house. This specialty method is creating a lot of interest in the print world, being able to use image transfer technology that will bond with digital ink. When users avail of sleeking they will immediately set themselves apart from the crowd. This process has been used to produce items such as wedding stationery, business cards, greetings cards, promotional print, and even university certificates where individual names can be printed in gold.

How It’s Done

The process could not be simpler. A sheet of paper is put through a digital printer, and wherever you put toner you then pass the sheet through the laminator. As it goes through the laminating process, the foil comes off the carrier film onto where the toner is. It’s similar to foiling. Then put the sheet back through the digital printer and you can print on the background, for example, to give a completely different effect.

Step 1. Separate the image and digitally print the section that you want Sleeked in black, deleting all extra details. The image transfer technology will bond to the digital ink.

Step 2. Run the print through the laminating machine with your desired finish such as gold, silver or a colour.

Step 3. Digitally overprint to create a layered high impact print.

The technology opens up a completely new revenue stream for users, saving both time and money compared to outsourcing. Using just one system to laminate, foil and spot UV offers an even greater return on investment, as multiple applications are possible. In a digital age, decorative print finishes add an extra dimension to print.

Click here to request a Sleeking demonstration on the new GMP QTopic 380